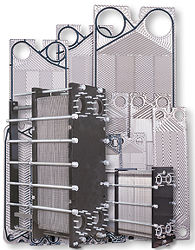

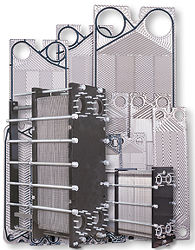

Plate Heat Exchangers utilize corrugated plates stacked between a fixed and a movable pressure plate. The corrugation patterns alternate for maximum operating pressures. As virtually all of the material is used for heat transfer, Plate Heat Exchangers can have large amounts of effective heat transfer surface in a small footprint. It is not uncommon that a Plate Heat Exchanger will have the same thermal capacity as a Shell and Tube five times larger.

The unique corrugation pattern pressed onto each Schmidt-Bretten thermal plate produces the highest overall heat transfer rate by assuring highly turbulent flow and excellent fluid distribution across the entire surface. With high heat transfer rates and true counter current flow, API Plate Heat Exchangers economically handle close temperature approach requirements.

API Heat Transfer's line of Schmidt-Bretten Plate Heat Exchangers incorporate superior design features to ensure long term customer satisfaction.

- Highest quality gaskets precisely fit the plate grooves for positive sealing and ease of maintenance.

- Superior clip-on gasket design ensures proper fit during closing of the unit.

- Double sealing design prevents the possibility of mixing the two process fluids. Leak detect feature ensures any leakage is to the atmosphere.

- Zinc coated hardware provides long life.

- All plate pack tightening is done from the fixed pressure plate to eliminate any stud interference.

- All bolted construction for easier service.

- Low volumetric fluid hold-up provides quicker response to heating and cooling demands, while reducing costs for more expensive process fluids.

- Readily expanded for greater capacities, or totally new applications.

- Available in a variety of plate sizes for industrial, HVAC or sanitary applications.

Typical applications include:

- Chemical

- Pharmaceutical

- Food and Beverage

- Dairy

- HVAC

- Marine

- Oil Cooling

Frame: Painted Carbon Steel, or 304 Stainless Steel

Plates: Stainless: 304 and 304L stainless; 316 and 316L stainless

Exotics: Titanium, Titanium-Palladium, SMO-254, Incoloy 825, Nickel, Hastelloy, Monel, Inconel, Tantalum

Gaskets: Nitrile, EPDM, Viton, Compressed Fiber, Glued or Clip-on designs

Connections: FPT, MPT, Studded, Flanged, Tri-Clamp, others

Capacities: 0.5 GPM to 8800 GPM

Codes: ASME

Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance. The SB-Series features corrugated plates that produce highly turbulent flow in a true counter-current direction. This results in high efficiency and a very compact heat exchanger design. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice.

API Heat Transfer Brazed Plate Heat Exchangers are available for process and refrigeration applications. Made from stainless-steel plates and copper or nickel brazing materials, they are suitable for a wide variety of heat exchanger applications.

Typical applications include:

- Refrigerant Evaporating Condensing

- Heat Pumps

- Steam Heating

- Engine or Hydraulic Oil Cooling

- District or Zone Heating Systems

- Swimming Pool Heating

- Various Heating and Cooling Duties

Plates: 316 Stainless Steel

Braze Material: Copper Nickel

Connections: 3/4" to 4" NPT, Soldering SAE Type, Flanged

Capacities: 20 GPM to 385 GPM, 1/2 Ton to 100 Ton

Approvals: UL Stamp ASME UM stamp is available by special order.

Welded Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial applications. Built entirely from 316 stainless steel, they provide exceptional corrosion resistance. The exchanger features corrugated plates that produce highly turbulent flow in a true counter-current direction. The result is high efficiency in a very compact design. Due to the smaller size and reduced material content, welded plate heat exchangers can be the most economical heat transfer choice.

The standard design has all piping connections located on one end of the heat exchangers. This simplifies installation and maintenance costs. Many times, the piping alone is all that is required to adequately support the heat exchanger, thus eliminating support considerations and labor costs in packaged equipment.

API welded plate heat exchangers have narrow flow channels and reduced liquid volume needs. Due to their efficiency, they can be selected to use less coolant.

The exchanger design features plates with computer-designed corrugations in a "chevron pattern" that is alternated from plate to plate. The plates are then bonded together at their contact points. This yields a strong, unitized construction. Gaskets common to other technologies are eliminated.

The unique capabilities of the API welded plate heat exchanger makes it suitable for a wide range of applications that extend beyond refrigeration including:

- Process chemicals

- Oil cooling

- Caustic soda

- Heat transfer fluids

- Hazardous liquids

- Expensive fluids

API Heat Transfer Semi-Welded plates feature plates that are welded using advanced laser welding techniques. Two plates are welded together and are fitted with a Viton® O-Ring and/or Teflon® gasket liner. The resulting plate pack has every other plate fully serviceable, while maintaining integrity of the welded plate pair.

This is especially suitable for critical fluids and gases, such as ammonia or caustic process chemicals where fluid loss is not acceptable. In the case of ammonia refrigeration, the reduced volume results in significant savings.

Frame: Painted Carbon Steel, or 304 Stainless Steel

Plates: Stainless: 304, 316 and 316 Ti

Exotics: SMO 254, Titanium

Gaskets: Chloropren; PTFE Sleeve

Connections: Studded, Flanged

Capacities: 3 to 3,000 GPM

Schmidt-Bretten Plate Heat Exchangers

12-page catalog. Provides information on our complete range of plate products. Specifically highlights our plate & frame construction. Information includes advantages, design parameters, plate configurations, models and capacities, and available options.

Schmidt-Bretten Brazed Plate Heat Exchangers

8-page color brochure. Complete information on API's brazed plate heat exchangers including models, typical applications, dimensions, capacities and materials of construction. Also details benefits over other heat transfer devices.

Schmidt-Bretten SIGMAWIG All Welded Plate Heat Exchangers

6-page brochure. Discusses the features and benefits of Schmidt-Bretten SIGMAWIG welded PHEs. Lists available construction materials, specifications and dimensions.

Plate and Frame Heat Exchanger Installation and Maintenance Manual

A comprehensive users manual containing complete instructions on installation, service and maintenance for plate and frame heat exchangers.

Gasketed Plate and Frame Heat Exchanger Animation

This computer generated animation provides an overview of the disassembly of a Plate Heat Exchanger.

Schmidt-Bretten Brazed Plate Heat Exchanger

A comprehensive users manual containing complete instructions on installation and maintenance for brazed plate heat exchangers.

The Heat Exchanger Mailing List

Ask questions, get advice, stay in touch with the heat transfer community.